| The Bottom - Part Two

To repair the blisters I had ground out I first cleaned them again and then wiped them out

with fiberglass solvent. I'd then mix a batch of epoxy and wet out the ground out area.

I'd mix up a batch of West epoxy with the 406 colloidal silica filler to a peanut butter

consistency and working with a plastic spreader fill, fair and smooth the blisters. One or

two larger blisters just got a wet out with epoxy, then I place a small circle of glass

cloth in the hole and wetted it out. This would be repeated a few times with larger pieces

of cloth. These too got finished off with the 406 - epoxy mixture. Once cured I'd sand,

wash and wipe down with the fiberglass solvent.

The tan patches are thickened epoxy applied where I fixed blisters.

Once the bottom was smooth again I did a epoxy barrier coat. I

used the West System Epoxy again with their barrier coat additive. I did a few coats of

this. It too got a light sand after it was set to give the bottom paint some 'tooth' to

attach to.

Applied Barrier coat.

Barrier coat on fiberglass part of bottom

I put on three coats of Interlux Bottomkote bottom paint.

I retaped the other side of the water line and put on a nice

bright blue cove stripe and a stripe below the rub rail. Make sure you bite the bullet and

buy the good fine line masking tape. The tan junk most of us are familiar with is

awful, it doesn't make a clean line and doesn't remove cleanly.

The metal part of the keel was covered with pits and rusty

spots too. I slathered on a lot of navel jelly to remove the worst of the rust. I repeated

this the next day. Then I did a bit of work with the grinder and pressure washer.

Finally I used the West Epoxy and filler again to fair the keel too. Same as the bottom

basically, with barrier coat, then bottom paint to finish it off.

Cleaning up the lower (metal) part of the keel

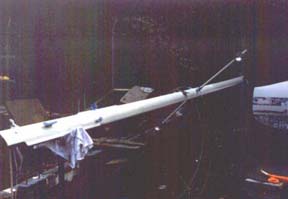

The mast and boom looked awful too. I washed them

down and then painted them with a acid etching primer designed specifically for aluminum.

Paint doesn't adhere to aluminum well without this step. I painted the mast and boom with

the same single part polyurethane as the hull, also rolled and tipped. One good tip is to

start at the top of the mast. You'll make your mistakes at the beginning as you figure out

how to do it and they'll be difficult to see mistakes at 25 feet or more above deck...

I removed the gate valves that were in the boat

and replaced them with bronze ball cocks. There are two blake seacocks, of the cone type

construction. They are integral with the through hull fitting. This time around I just

disassembled them and cleaned them up. I put valve grinding paste in the fitting and

worked the valve around (a lot). Then I cleaned up, lubed and reassembled. They aren't

seized any more but they still don't work like they should. I guess I'll replace them

completely in the not too distant future.

I also drilled a hole in the bottom for the new

paddle wheel like speed transducer. I epoxied the edge of the 2 inch hole after drilling

it to prevent water seeping in between the laminate. The speed instrument I installed is a

Raytheon ST50. You can withdraw the transducer from the fitting from inside the boat and

replace it with a supplied plug while you clean the paddle wheel. (So you can clean it of

weed etc. to keep it working well.) The nifty thing about this system is the through hull

has a little flap door the closes as you withdraw the transducer. This means you only get

a few tablespoons of water in the boat when you make the swap instead of a fountain.

I re applied new registration numbers and waited

for the marina crew to come fetch TOYOT back to the water...

Here's the hydraulic trailer they use. No travel lift here I'm afraid.

This trailer has a keel support bar and four arms that all adjust hydraulically. They tow

it around witha tractor.

Backing TOYOT down to the crane...

After they slings are in place and supporting the boats weight the

trailer arms are dropped and the trailer removed.

Here we are back in the slip. I've taped off deck hardware to do some

painting of the deck next. Same paint and methods as the hull.

All the books will tell you to remove all the hardware and not try to

paint around it. Partly to 'get a better seal'. If this 31 year old boat has hardware that

ain't loose or leaking yet, I'm sure as heck not taking it off! I masked and painted

around it.

Here the foredeck is done, weather deck not yet for comparison. The non

skid areas were done in a grey, which I might do when I do the last coat on the non skid

areas with some non skid silca added.

more painting...

results...

The finished paint job...

|